Zinc Anodes Aluminum Anodes Magnesium Anodes

Harbor Island Supply produces zinc anodes and aluminum anodes for Cathodic Protection. HARBOR Zinc Anodes conform to the MIL-A-18001K and MIL-DTL-18001L(3) alloy , while HARBALUM Aluminum Anodes meet MIL-A-24779 and MIL-DTL-24779 alloy.

Magnesium Anodes: Cast Magnesium Anodes and Packaged Backfill Magnesium Anodes meet AZ63, Alloy H-1 Grade A, Grade B or Grade C. Extruded Magnesium Rod meets AZ31 (GalvoRod Alloy). Magnesium Anodes are available as either bare or with plastisol coating for marine use. Packaged Backfill Anodes are for ground installations, and magnesium rods for boiler and tank systems.

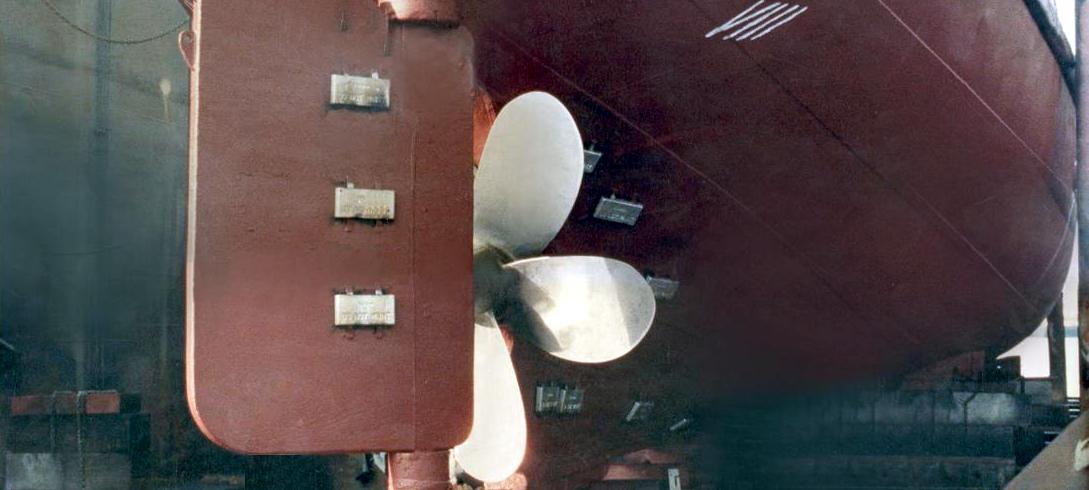

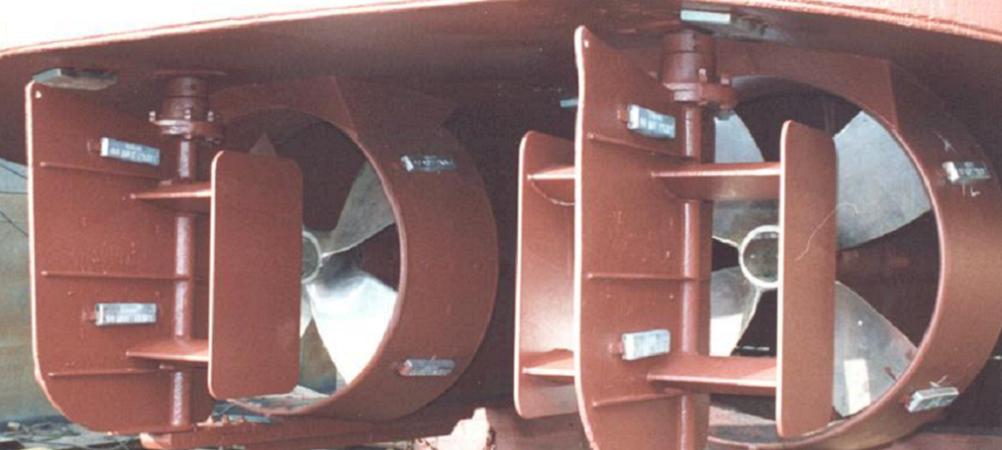

Protecting Vessels & Structures

New research occasionally upgrades revisions to the U.S. Naval Military Specifications Mil-A-18001 / MIL-DTL-18001 (Zinc Anodes) and MIL-A-24779 / MIL-DTL-24779 (Aluminum Anodes). Harbor Anodes follows these latest improvements.

For quality anodes, always ask for Harbor Anodes.

Customers include: US Navy, US Coast Guard, US Army Corps of Eng, state govts, universities, research companies, oil companies, ect.

Galvanic Corrosion

Galvanic Corrosion is created when metals of different potentials are attached to each other and submerged in water or any solution that carries electrical current. Since different metals corrode at different rates, a current flow will be created from the faster corroding metal (anode) to the slower corroding metal (cathode). A reliable anode must be capable of continuously supplying electrical current throughout its life. HARBOR anodes are made from high purity base metals before being alloyed with controlled amounts of additives to enhance electrochemical properties and to offset the small amount of impurities that detract from current output. Improper or unalloyed anodes start off with a high current output which tapers off over time, thus providing insufficient current for long term protection.