Leaders in the Production of Anodes For Over 40 Years

▪️ Family-Owned ▪️ Fast Turnaround ▪️ High Quality at the Right Price

HARBOR ISLAND SUPPLY is a third generation family-owned casting facility operating out of a 23,000 square foot plant in Seattle.

We’ve been manufacturing and distributing zinc, aluminum, and magnesium anodes for cathodic protection since 1981.

Custom Casting

If you want it, we can make it.

Our in-house machine shop allows us to quickly design and build molds for custom or special orders.

We can alter existing designs to fit any need, or come up with a new design to fit a particular application, all at a reasonable price.

No production run is too large or too small for us.

Casting temperatures are computer controlled and cores are prepped to enable proper bonding between the anode and the core, allowing for maximum current output.

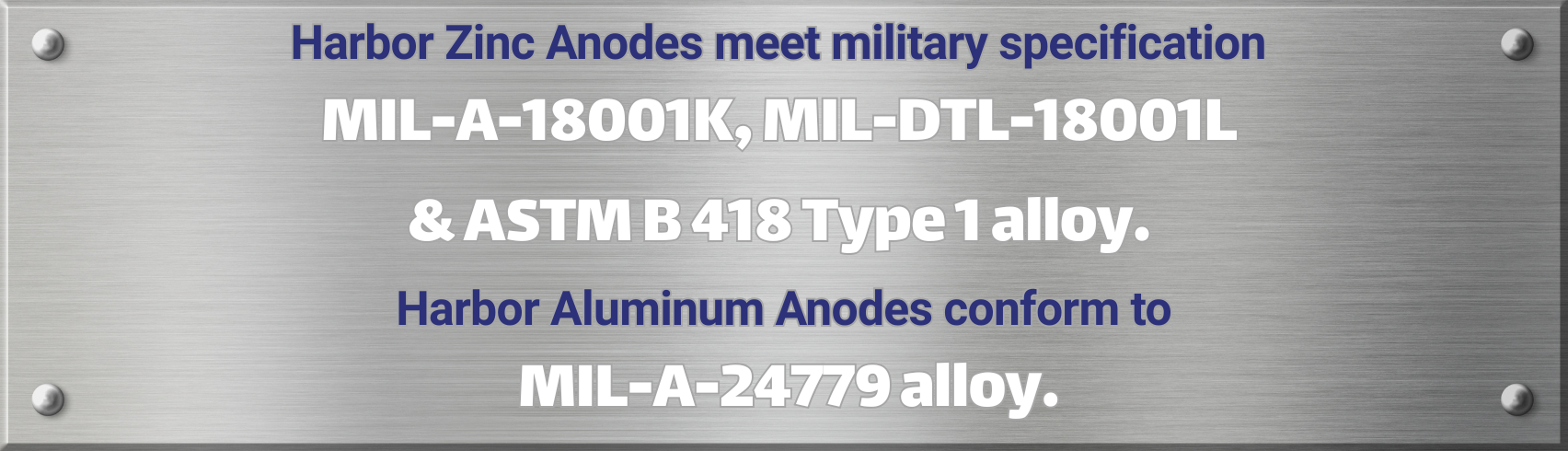

HARBOR ANODES are produced to the latest military specifications with virgin, high-purity metals before adding controlled amount of additives for the alloys to ensure quality.

Harbor Island Supply has been entrusted to protect vessels and structures from an array of customers including the U.S. Navy, U.S. Coast Guard, U.S. Army Corps of Engineers, oil companies, universities, research companies, and state governments.

Protecting Vessels & Structures

Galvanic Corrosion is created when metals of different potentials are attached to each other and submerged in water or any solution that carries electrical current.

Since different metals corrode at different rates, a current flow will be created from the faster corroding metal (anode) to the slower corroding metal (cathode). A reliable anode must be capable of continuously supplying electrical current throughout its life.

Improper or unalloyed anodes start off with a high current output which tapers off over time, providing insufficient current for long term protection.

HARBOR ANODES are made from high purity base metals before being alloyed with controlled amounts of additives to enhance electrochemical properties and offset the small amount of impurities that detract from current output.

What You Can Count On When You Choose

Harbor Island Supply

Huge Selection

We offer a wide array of products manufactured to meet any need, whether for commercial use or pleasure craft, in all types of water.

Our staff can assist you in discovering which of our products best meets your needs. If we don’t already have what you’re looking for, we’re always happy to make it for you!

Fast Turnaround

Many of our products are already in stock, and we’re making more every day.

Tell us when you need your anodes, and we’ll find a way to accommodate your schedule.

We use a variety of shipping partners to ensure that our products get to you on time.

Industry Expertise

With four generations in the business of corrosion protection, you could say expertise runs in the family.

Our staff has devoted their entire careers to manufacturing and selling anodes. Decades of knowledge and experience are ready to be passed onto you as soon as we take your call.

Fast Turnaround

▪️

Wide Selection

▪️

Custom Casting

▪️

Family-Owned

▪️

High Quality at the Right Price

▪️

40+ Years of Industry Expertise

▪️

Meets Latest Military Specs

▪️

Fast Turnaround ▪️ Wide Selection ▪️ Custom Casting ▪️ Family-Owned ▪️ High Quality at the Right Price ▪️ 40+ Years of Industry Expertise ▪️ Meets Latest Military Specs ▪️